For years my collection consisted entirely of records with origins dating back no further than the late ‘60s. But after numerous purchases as a novice collector of vintage jazz records, I noticed a new type of noise. These LPs were not in the greatest shape visually, but pops and ticks weren’t the real issue. Many of the records had this fuzzy sound to them that I had never heard before. I didn’t understand what I was hearing, so I began looking for an explanation.

I soon learned that the grooves of these records were worn in a way that my more modern stereo LPs weren’t. But why did this noise only seem to exist with older mono records? This article explores the possible reasons for this unwelcome phenomenon and a few strategies for avoiding it.

What causes groove wear?

If an unworn stylus follows a groove properly, instances of wear should be extremely low. Problems arise when records are played with worn styli and when the stylus fails to track the groove properly, a phenomenon called mistracking. Mistracking is generally promoted by a combination of very high (or low) tracking forces and low lateral compliance. It is also more likely to occur during passages where the groove has extreme modulations, including any combination of dynamic peaks, upper-midrange frequencies, and envelopes with fast attack times (for jazz, brass and pianos especially). Mistracking is also common at the innermost part of each side where the modulations are packed together tighter than at the outer edge (for more information on inner groove distortion, also know as “the pinching effect”, see this helpful Hydrogen Audio thread). Over time, a setup that mistracks consistently will wear a groove to the point of audible distortion.

Stylus Material

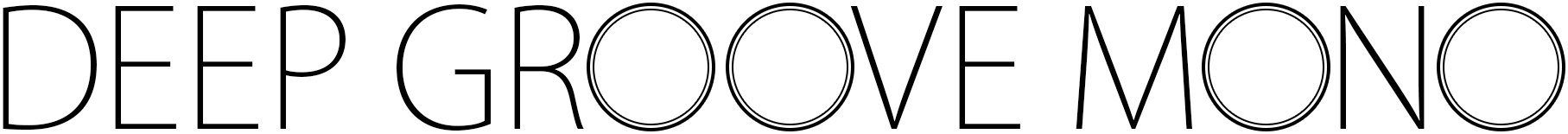

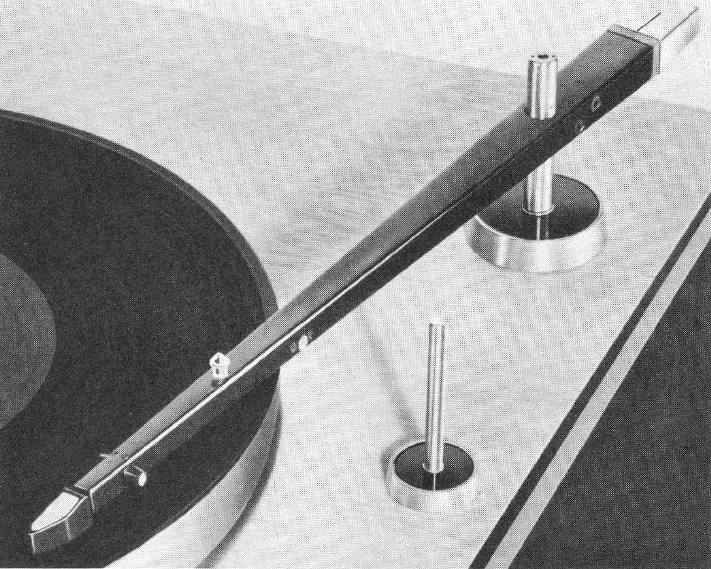

Although diamond-tip styli have been the industry standard for decades now, inferior styli were commonly used in the ‘50s and into the ‘60s. As an example of this, from 1949 to 1961 Shure Brothers, Inc. produced their W-series cartridges and replacement styli for their own phonographs and countless others made by companies like RCA, Admiral, Electro-Voice, and Sonotone. These cartridges, designed for playing microgroove LPs, used quick-to-wear osmium and sapphire styli (1). Osmium was only good for around 10 plays and sapphire lasted at least 35 plays but no more than 75, while the new (and much more expensive) diamond tip guaranteed hundreds of hours of worry-free playback. But users of osmium or sapphire tips wouldn’t even know that their stylus was worn or damaged until it was too late. From the book Hi-Fi All New 1958 Edition:

|

| 1. Osmium stylus after 50 hours of use — would cut glass let alone soft vinylite 2. Sapphire stylus after 50 hours has lost its rounded tip 3. Diamond stylus after 478 hours is still correctly shaped, merely rubbed |

By the time stereo came around in the 1960s, the diamond tip slowly became the industry standard in both mono and stereo cartridges, and osmium and sapphire would no longer pose a threat to vinyl LPs.

Tracking Force

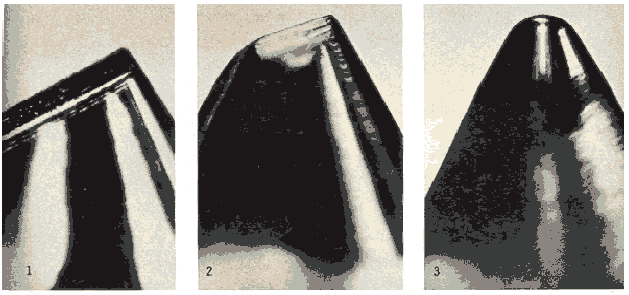

The audio industry certainly has a skewed interest in promoting new products with literature explaining how technological advancements can improve your listening experience. In their 1957 product catalog Shure claimed, “It has long been recognized that elimination of record and stylus wear requires that tracking force be reduced below the level of 2 grams” (1). That may have been a rather conservative estimate intended to promote Shure’s new Studio Dynetic tonearm-cartridge combo, designed to track at just 1 gram of force (“dynetic” was a term Shure coined for “moving magnet” that ultimately failed to catch on).

|

| The Shure Studio Dynetic Tonearm |

These types of ads sometimes even go as far as damning past products as harmful. Later in 1960 the company touted, “The way a cartridge is made and its operating characteristics determine the weight at which it tracks records…The lighter the tracking force, the less the record wear…3 grams to 5 grams weight are optimum tracking forces…This affords good record protection and assures long stylus life. Do NOT use a cartridge that needs a minimum tracking force in excess of 6 grams to operate properly!” Further down the road in 1968, as part of a rather scientific presentation of the theory behind the new V-15 Type II stereo cartridge, Shure proclaimed that “increasing tracking weight to force the stylus to stay in the groove will literally shave off the groove walls” (1).

Perhaps the Shure literature includes a healthy dose of persuasive propaganda aimed at selling new products, but Shure clearly had a vested interest in designing lighter-tracking carts at that time. From 1949 to 1956, Shure’s crystal and ceramic W-series carts, intended for tracking mono microgroove LPs, had minimum tracking forces between 7-9 grams. Then in 1957 we see those numbers decline to 4-8 grams. As for higher-end “audiophile” mono carts, Shure released the ML44 mono cartridge in 1955. It tracked between 5-8 grams, had sapphire and diamond options, and was in production until 1960. The M5D would eventually replace the ML44 as Shure’s flagship mono cart. It was in production from 1958-1966 and had a range of 2-6 grams (1).

|

| The Shure ML44 and M5D cartridges |

Many other companies were working to reduce tracking force as well. Fairchild’s 200 series was introduced between 1953 and 1955 and had recommended tracking forces of 4-8 grams. Then in 1958, the 230 hit the market with a range of 2-6 grams (2). Pickering’s model 240 was offered with a range of 4-8 grams in 1955, then in 1965 the U38 with optional mono stylus was marketed as having a range of 2-5 grams (2 & 3).

There are many other examples of high-tracking mono carts from this era, some of which used sapphire styli. Ortofon’s AB and AD mono carts had used sapphire styli since 1948, and their “Standard” A model cartridge had a recommended tracking force of 7 grams (2 & 4). Ortofon’s sister U.S. company, Electro-Sonic Laboratories, was making the Soloist (sapphire and diamond options) and Concert (diamond) carts into 1957 with ranges of 3-10 and 3-7 grams, respectively (5 & 6). In 1958 GE’s VR II was introduced with a sapphire stylus tracking at 4-8 grams (7). And as late as 1966, Sonotone was selling crystal and ceramic mono carts designed for use with microgroove records that tracked between 4 and 10 grams (8).

|

| 1957 Ortofon advertisement |

Although there is a trend to track at the higher end of recommended ranges today, it’s possible that mid-century consumers erred more on the side of caution. In a 1955 Audio Magazine review of the ESL Concert cart, the company reported that tracking at the minimum force of 3 grams was “adequate”, suggesting that today’s audiophiles are less worried about wear than their audiophile ancestors. But tracking too light can cause severe mistracking under any circumstances, and while tracking at the higher end of today’s lower ranges is considered safe practice, tracking at the higher end of the ranges back then certainly would have increased the potential for wear.

From this history of tracking forces, one might conclude that consumers and cartridge manufacturers had a cooperative interest in technological developments that reduced tracking forces in response to groove wear.

Lateral Compliance

Although I originally only took worn styli and high tracking forces into consideration in forming my hypothesis, Cohearent Audio vinyl mastering engineer Kevin Gray explained in a telephone conversation that low lateral compliance should also be suspect for causing groove wear on vintage mono LPs. Before stereo sound, static or “vertical” compliance meant nothing to a consumer. Since monophonic LPs have no vertical information in their grooves, the first mono cartridges only had enough vertical compliance to accommodate unruly vertical motions of the stylus caused by warps, foreign debris, or forcefully plopping a needle onto a record. The hot topic of the day instead was lateral compliance, also known as dynamic compliance, which measured the amount a stylus was allowed to move in the horizontal plane.

The lateral compliance of a mono cartridge reflected its tracking force. Higher tracking forces required a firmer support system beneath, which called for lower lateral compliance. In these instances, more force was required to move the stylus, and this took its toll on the groove. The stylus traced the groove accurately but there was more friction and hence a greater chance of wear. This was a key factor in companies developing technology that would lead to lower tracking forces.

To this day static a.k.a. vertical compliance is a spec rarely listed by cartridge manufacturers, and for modern mono cartridges — most of which are equipped with vertical compliance — specs for dynamic compliance range from 7 to 20 cu (short for “compliance units”, measured in centimeters per dyne or microns per meganewton). The Ortofon CG 25 and Miyajima Zero, two modern mono carts designed without vertical compliance, are the only carts in that list with compliance specs below 12 cu (9-12). On the other hand, specs for mono carts in hi-fi’s heyday indicate lateral compliance between 1.5 and 6.8 cu (1, 2 & 5).

In 1968 Shure made clear the connection between low lateral compliance, high tracking force, and groove wear. In addressing the challenges styli face when confronted with unruly transients and low-frequency content, Shure claimed:

This suggests that the lower lateral compliance of vintage mono carts is in part to blame for the groove wear we find on vintage mono records today.

What does groove wear sound like?

‘Fuzzy’ is a good word to describe it. ‘Crackly’ is another, but it’s not to be mistaken with the crackle caused by surface marks; crackling caused by groove wear is more apparent during dynamic bursts corresponding with louder moments in the program. If you’ve never been able to identify groove wear by ear or you’re having a hard time imagining what it might sound like, I have included an audio comparison here. Upon listening it’s not hard to hear the damage done in hi-fi’s distant past:

Unworn copy:

Worn copy:

What Does Groove Wear Look Like?

Though it doesn’t seem to be an exact science, groove wear can manifest as clusters of miniature greyish lines running with the grain of a record’s grooves. At a distance, this can cause a record to look slightly dull, as if it has lost some of its original glossy finish. But even if you know what to look for it can still be tough to spot.

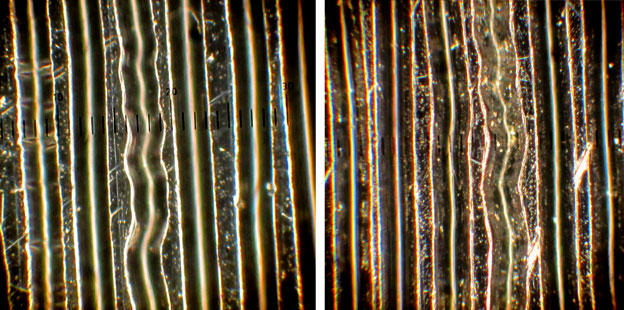

Below are photos provided exclusively to Deep Groove Mono by Kevin Gray comparing the grooves of worn and unworn copies of the same title from the same pressing run. As pointed out by Gray, you should be able to see the regular presence of wear on the upper part of each groove wall in the photo to the right.

|

| Grooves without (left) and with (right) wear |

|

| Grooves with and without wear (photos optimized with filters for added emphasis) — notice the thicker black area of the groove on the left representing smooth walls versus the greyish, spotted area of the groove on the right indicating rough, worn surfaces |

Mastering and the Prevention (or Promotion) of Groove Wear

Vinyl mastering engineers have a difficult job. They are expected to cut a record with great signal-to-noise ratio, but at the same time the record should not be prone to mistracking. In the heyday of high fidelity vinyl playback, many studios played it safe, cutting their records at a moderate volume. Since the dynamic peaks of these LPs are less extreme, groove wear is less likely to settle in. However, pops and ticks are then more likely to overpower the music as marks collect on the record’s surface over time. I have found that vintage jazz records cut by labels like Columbia, Atlantic, Contemporary, and EmArcy generally fall into this category.

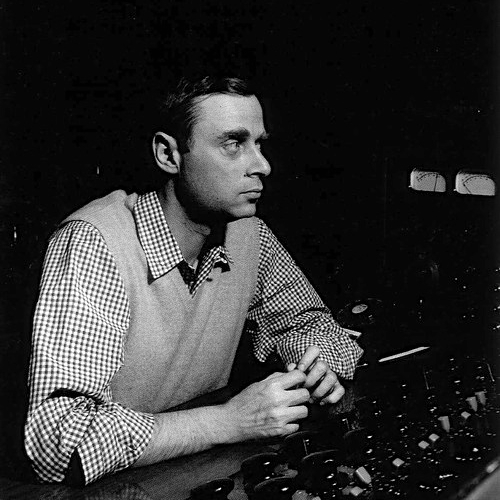

Other mastering engineers worked to obtain a superior signal-to-noise ratio and took more risks in the process. They applied heavier doses of compression and used more extreme high-frequency filtering to cut their records as hot as possible without causing skips. This allowed the music to easily overpower surface noise, but the tradeoff was that over time the record would be more susceptible to wear caused by mistracking. Rudy Van Gelder, the darling of vintage jazz collectors everywhere, was the most infamous proponent of this technique. He is also responsible for hundreds of the most collectible classic jazz LPs released on labels like Blue Note, Prestige, New Jazz, and Impulse. So while the higher amplitudes of Van Gelder’s masters will usually dominate pops and ticks, these records are also more likely to have excessive wear dating back to hi-fi’s infancy.

|

| Rudy Van Gelder |

Ironically, this approach to mastering is probably one of the reasons why Van Gelder originally won over so many industry types. The technique’s benefits would have been immediately apparent, making Van Gelder’s cuts the toast of the New York bop scene. On the other hand, any combination of worn styli, high tracking forces and low compliance made these records more prone to wear, and we can hear the consequences decades later.

In the process of updating and expanding my research, I was pleasantly surprised to find Shure echoing several of my original conjectures. From the aforementioned 1968 catalog:

All hope is certainly not lost for collectors of Blue Note and Prestige originals though. If a record was properly cared for and made it through the ‘50s and ‘60s in tact, it’s quite likely that it traveled the remaining distance to us today safely as a result of all the technological improvements that followed. Vintage jazz records of this elite class may not be available in abundance today but they do exist, and the needledrops in the Vinyl Spotlight posts here on Deep Groove Mono should serve as evidence.

“Vintage Jazz Records Sound Better Than They Look”

There appears to be a popular sentiment in the jazz collecting community that vintage jazz records sound better than they look. While I have found this to be true in instances where a hotly-mastered record was scuffed up but wear-free, there have also been many occasions where a record virtually free from surface marks was concealing the distorted scars of yesteryear.

Why don’t the majority of sellers address the phenomenon of groove wear in their auction descriptions? It could be because most sellers simply don’t play grade and groove wear is more difficult to identify on sight than surface marks. It also might be because groove wear is more prominent near the center of a record (think inner groove distortion), and even if a seller play grades they may only give a quick listen to the beginning of each side.

Yet another possible reason why groove wear’s existence is on the hush might be because most listeners may not even notice it. In its mildest form, distortion from wear will only be audible to the most discerning of ears at the end of each side, and when it does pop up it will only be audible intermittently during louder moments in the music. This contrasts with the regular popping and clicking of surface noise. Keeping in mind that groove wear is less common with stereo records might then explain why many people’s ears seem more accustomed to the consistent crackle caused by marks on a record’s surface.

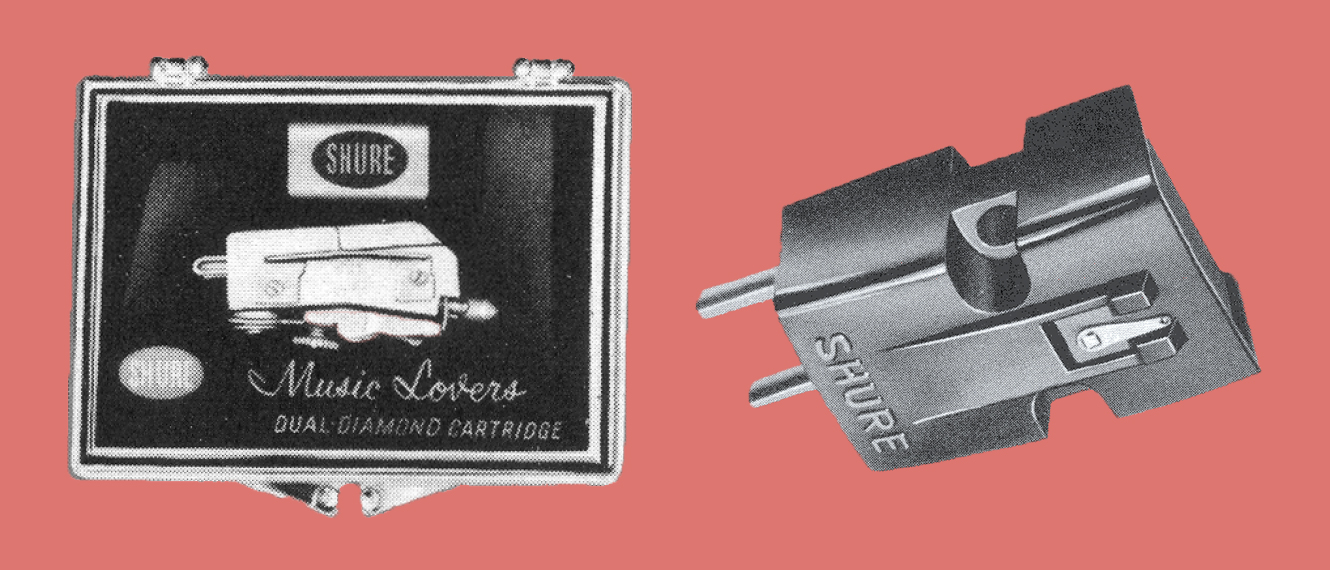

Can a “true” mono cartridge help distortion from wear?

After reading and hearing numerous opinions on the topic, it’s clear that the definition of a “true” mono cartridge is open to interpretation. Some collectors (and engineers) believe that a true mono cart can have two coils so long as they are realigned perpendicular to the horizontal surface of the record in an effort to ignore vertical modulations of the stylus (this is opposed to the 45-degree alignment of the coils in a stereo cartridge). Most modern mono carts incorporate this dual-coil design (13 & 14). Other collectors believe that a true mono cart must only utilize a single coil the same way vintage mono carts did, and the Denon DL-102, Ortofon CG 25, and Miyajima Zero are all examples of this (12, 14 & 15). Yet some go even further, believing that a true mono cart also needs a 1-mil stylus and no vertical compliance, which is only found today on the CG 25 and Zero (12 & 14). (For more information, see the Deep Groove Mono Cartridge Database.)

|

| The Ortofon SPU Mono CG 25 Di MkII cartridge |

I personally have experience with the Grado MC+ (dual realigned coils, vertical compliance, 0.7-mil spherical stylus), and unfortunately my experiments with that cart failed to reduce distortion from groove wear in any significant way. I also experimented with the Ortofon OM stereo cartridge summed to mono while sporting a 1-mil D25M stylus, and again this combination was unable to cure the ills of wear. Below are two audio clips that compare 0.7-mil and 1-mil styli tracking a worn record:

Shure M44-G with 0.7-mil stylus summed to mono and tracking at 1.5 grams:

Ortofon OM with D25M 1-mil stylus tracking at 3 grams:

Conclusion

Groove wear has proven to be one of the greatest obstacles this hobby has to offer. What kind of preemptive action can an informed collector take to avoid ending up with these pesky records? Unfortunately, most online sellers don’t play grade, and it’s difficult for the untrained eye to see groove wear. Though it’s no guarantee, the best way to avoid groove wear is probably to only buy records online with high grades (VG++, EX, NM, M-) and to only buy records in person that retain their original glossy finish.

For one reason or another I’ve found that the majority of hobbyists rarely bring up the topic of groove wear despite its regular presence amongst original pressings of jazz LPs from the late ‘50s and early ‘60s. In this sense, groove wear truly is the elephant in the record store. I am simultaneously fascinated and frustrated by this, yet I encourage collectors to push on in search of those diamonds in the rough, those hard-to-find, amazing-sounding vintage jazz LPs that make all our efforts worthwhile.

Sources:

(1) Vintage Shure Catalogs (1933-1985) [shure.com]

(2) Vinyl Engine Cartridge Database (vinylengine.com)

(3) 1955 Pickering Product Catalog

(4) 1960 Ortofon Product Catalog (vinylengine.com)

(5) Perfection in Record Reproduction (1955 ESL Product Catalog) [vinylengine.com]

(6) Audio Magazine February 1957 Issue, page 67 (americanradiohistory.com)

(7) General Electric VR II Instruction Manual (vinylengine.com)

(8) Sonotone Phonograph Cartridge History (roger-russell.com)

(9) Grado Product Specifications (gradolabs.com)

(10) Ortofon True Mono Cartridges (ortofon.com)

(11) Lyra Kleos Mono Product Page (lyraanalog.com)

(12) Ammonite Audio Miyajima Zero A Product Page (ammonite-audio.co.uk)

(13) “My Dialogue with Grado RE: Their Mono Carts” (Steve Hoffman Forum Post) [forums.stevehoffman.tv]

(14) In correspondence dated March 20, 2017, an Ortofon representative explained that “all of (Ortofon’s) true-mono cartridges use (a) two-coil design, except for CG25 and CG65”, adding that “the single-coil is true-to-form, and the stylus is stiff as a board – no vertical compliance at all.”